Our product range

Lines

Types

Services & Consultancies

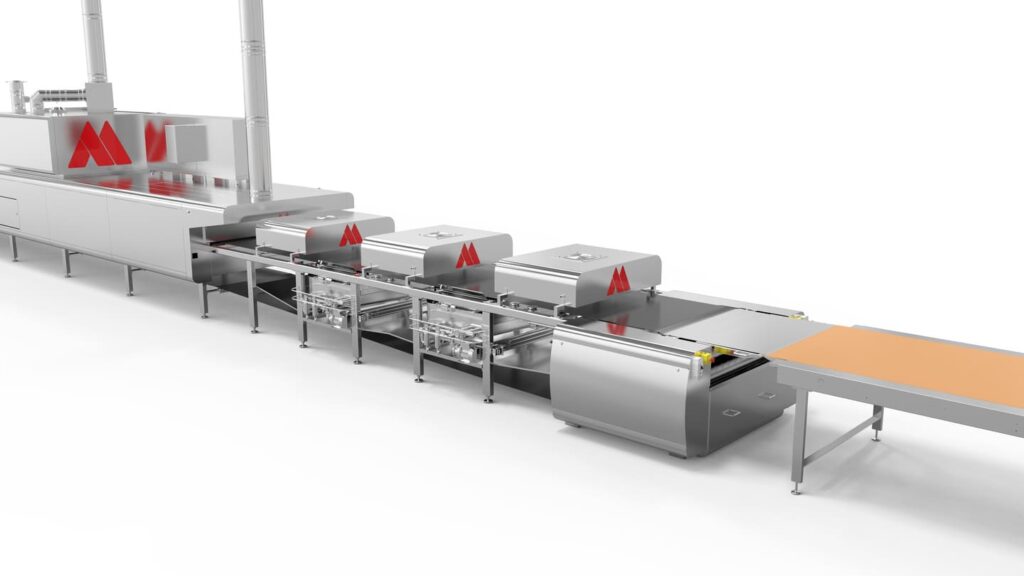

Jensen Line

- Capacity from 200 – 2,200 kg/hour.

- Suitable for the production of moulded articles with or without inclusions.

- Designed with low noise driving system with easy interactive HMI.

Universal Moulding Line

- Produce up to 10,000 kg/h – high-volume production with ease.

- Various chocolate moulding processes, including solid, shell, and FrozenCone®.

- Achieve consistent quality with our state-of-the-art depositing and cooling systems.

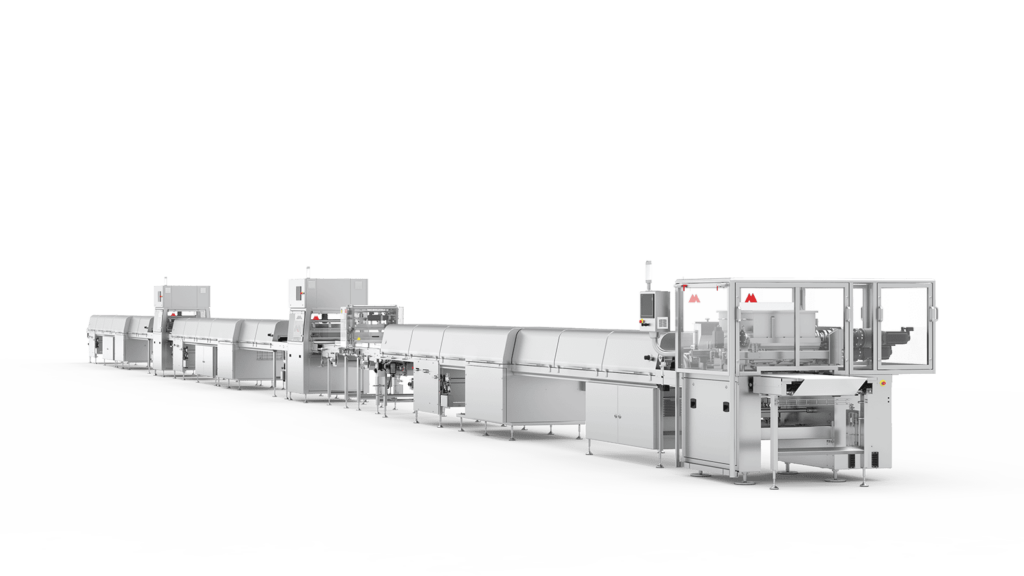

Confectionery Line

- Produce between 240 – 1,920 kg/h, perfect for scaling up your production.

- Achieve uniform size and shape with our advanced extrusion and cutting technology.

- Working widths ranging from 400 to 2x 800 mm and up to 2×16 rows across.

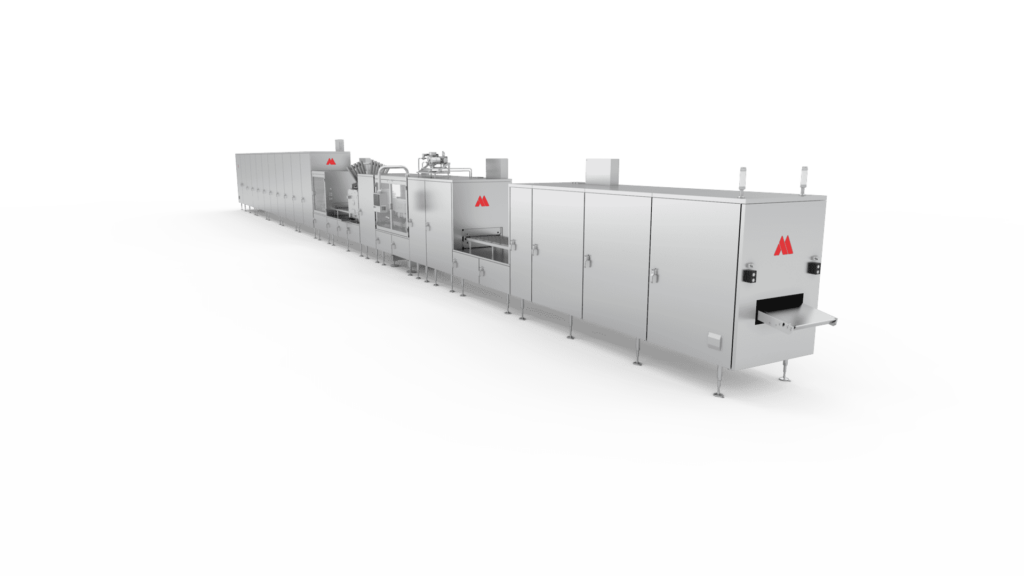

Steel Belt Line

- Handle production capacities from 250 to 6,600 kg/h.

- Ideal for producing chocolate chips, kisses, and shards.

- Achieve consistent product quality with advanced cooling and depositing systems.

Eriksen Line

- Handle production capacities from 225 to 2,000 kg/h.

- Ideal for various products including small lentils, balls, eggs, toffee, and centers for polishing or sugar-dragée.

- Achieve exceptional product quality with cooled precision rollers and state-of-the-art technology.

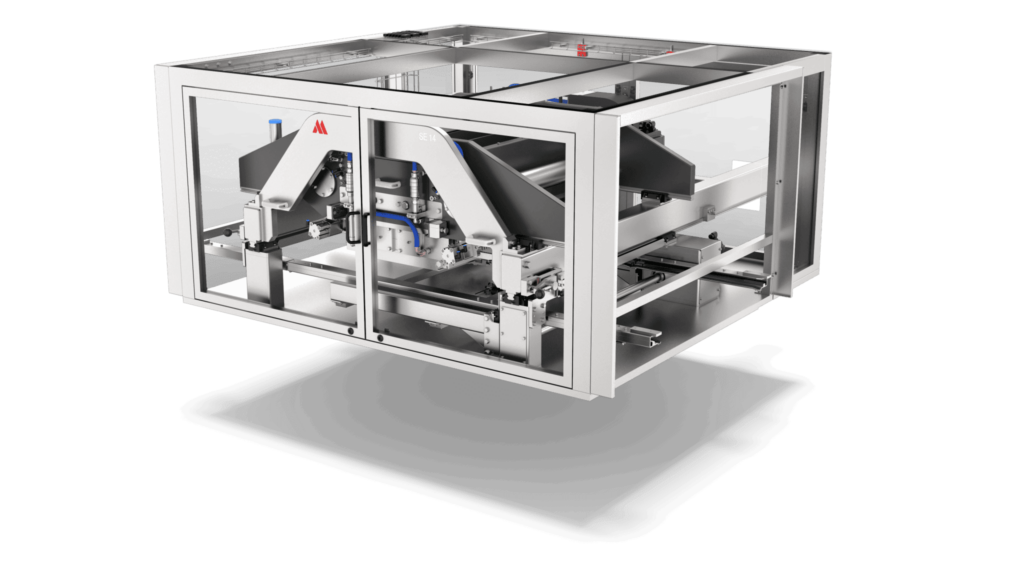

Bakery Line

- Handle production of cookies with fruit, nuts, and chocolate pieces, as well as multi-layer or multi-mass cookies.

- Ideal for producing fully and partially enrobed cakes, and bottom-enrobed baked goods.

- Achieve consistent product quality with advanced depositing and enrobing systems.

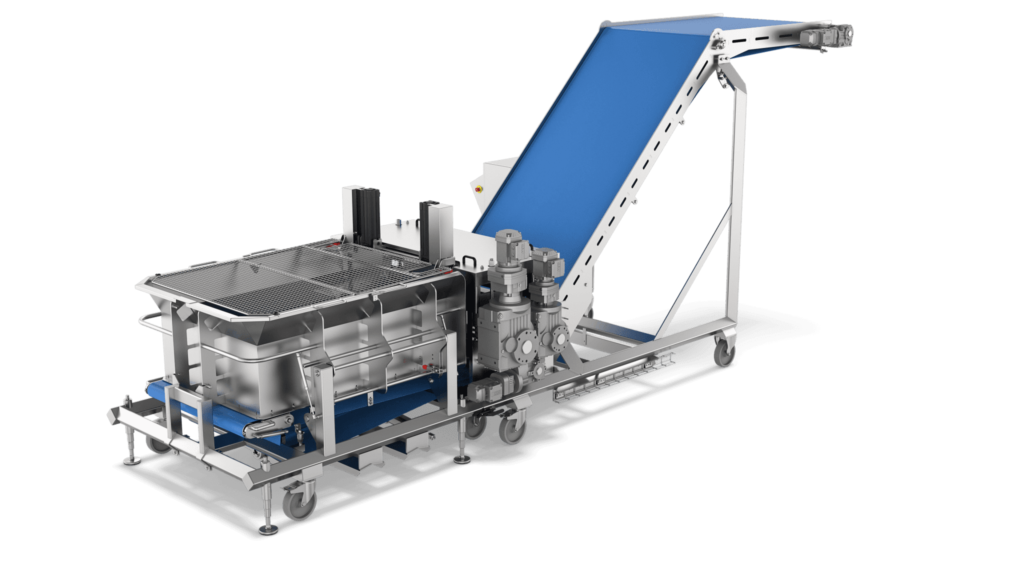

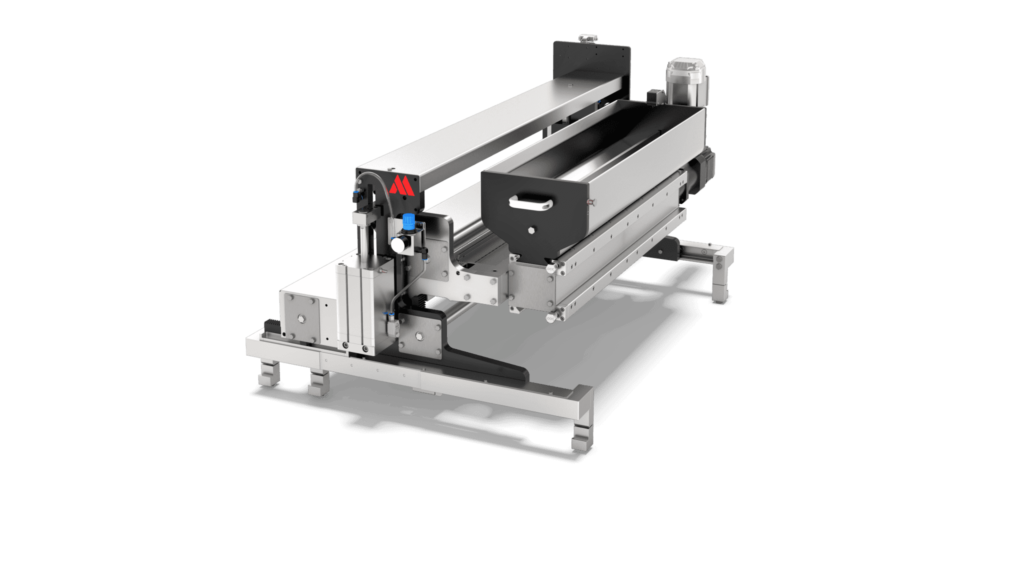

Dough Feeder

- Modular two-belt system ensures flexible dough control.

- Stainless steel construction allows full washdown.

- Integrated control system enhances reliability.

Nilshot Depositor

- Up to 30 different recipes.

- Up to 20 deposits per minute.

- 2 x 12 pistons.

Sophus Flexible Depositor

- High and low viscosity substances

- Perfect for small productions

- User-friendly cleaning and maintenance

EP2 Depositor

- Ideal for medium production as C-Frame.

- Perfect for larger production as In-line.

- Adaptable to wide range of ingredients.

SE 14 Depositor

- Energy efficient.

- Easy to clean and maintain.

- Compatible with all moulding lines

Bertha Stencil Depositor

- Width from 400-1200 mm.

- High precision and reliable forming.

- Allows for remote access.

StellaNova Temper

- Up to 40% shorter cooling time.

- Use up to 30% less energy.

- Up to 75% less chocolate waste.

SuperNova Orbit Temper

- Advanced temperature control.

- Temper from 600 – 2500 kg/h.

- Aeration down to 0.5-0.7 g/cm³.

AMC SuperNova Temper

- High quality tempered masses for any purpose.

- The right tempering technology regardless of your needs.

- Range from 50kg/h to 12.000kg/h.

SuperNova Energy Temper

- Reduces energy consumption by up to 30%.

- Creating stable beta V crystals.

- Range from 200kg/h to 12.000kg/h.

AMC SuperNova 50/100 Temper

- Capacity from 50 to 100 kg/h.

- Suitable for various masses.

- Advanced control and easy maintenance.

Master Enrober

- Stainless steel design for durability and easy maintenance.

- Band width from 850 to 2,600mm.

- Tempering control and optional bypass conveyor.

Bottomer Enrober

- Stainless steel design for durability and easy maintenance.

- Consistent, precise coating of products.

- Advanced closed water system.

Alice S Extruder

- Range of 600 – 1000 mm.

- Up to 2 heads for different masses.

- Handles up to 30 different recipes.

Junior Enrober

- Stainless steel design for durability and easy maintenance.

- Rapid changeover between enrobing materials.

- Equipped with a 400 mm infeed table.

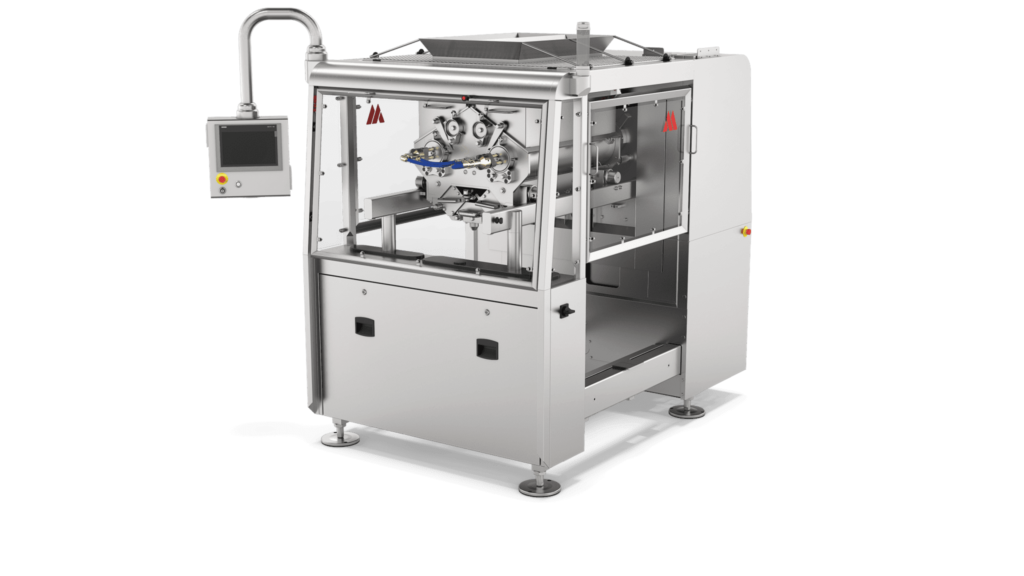

Alice C-Frame Extruder

- Flexible with QuickShift™ tools

- Extruding up to 150 liter/h per row.

- Features the FlexBooster™ & CamRotor™

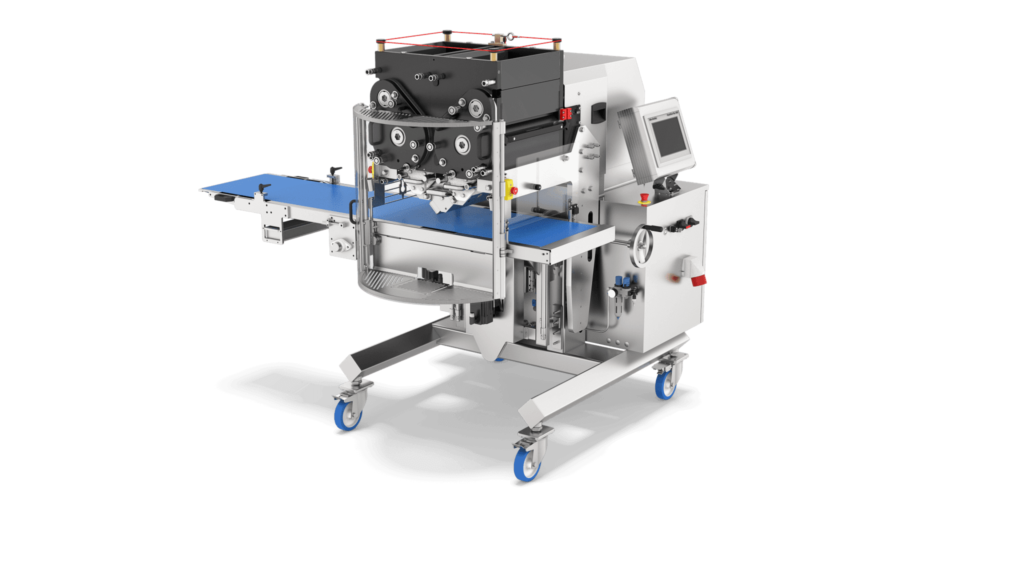

Alice Classic Extruder

- Easy access for cleaning.

- Quick wire cutter frame changeover.

- Fully adjustable cutting performance.

Alice I Extruder

- Easy to clean.

- Adaptable to different setups.

- Maintains product quality.

Alice II Extruder

- Create a variety of products.

- Quick changeover between productions.

- Easy access for cleaning.

Baby Flex Enrober

- 320 mm band width and 1,500 mm take-off table.

- Handles chocolate, compound and sugar coating.

- Adjustable shaker smooths and removes excess coating.

ChocoMeter+

- Precise temperature probe for fast, reliable data.

- Displays temper curve, TI, slope, and CTU.

- Built with durable materials for long performance.

ChocoAnalyzer

- Simulates cooling for contraction and crystallization.

- Monitors and adjusts tempering quality.

- Fits various chocolate and confectionery products.

Chip Depositor

Customer Service

- Ready to assist you inquiries.

- Troubleshooting and maintenance.

- Efficient operation.

Upgrades Service

- Enhance production processes.

- Save energy.

- Increase capacity of production.

Maintenance & Repair Service

- Keep your production running smoothly.

- Maintenance and repair services.

- Reduce your downtime.