Our product range

Lines

Types

Services & Consultancies

Jensen Line

- Capacity from 200 – 2,200 kg/hour.

- Suitable for the production of moulded articles with or without inclusions.

- Designed with low noise driving system with easy interactive HMI.

Universal Moulding Line

- Produce up to 10,000 kg/h – high-volume production with ease.

- Various chocolate moulding processes, including solid, shell, and FrozenCone®.

- Achieve consistent quality with our state-of-the-art depositing and cooling systems.

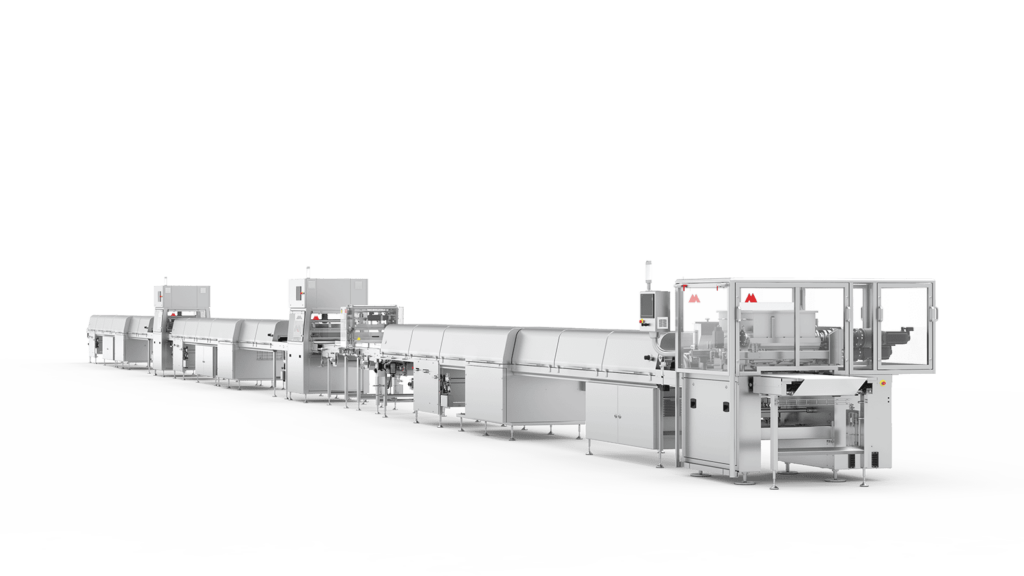

Confectionery Line

- Produce between 240 – 1,920 kg/h, perfect for scaling up your production.

- Achieve uniform size and shape with our advanced extrusion and cutting technology.

- Working widths ranging from 400 to 2x 800 mm and up to 2×16 rows across.

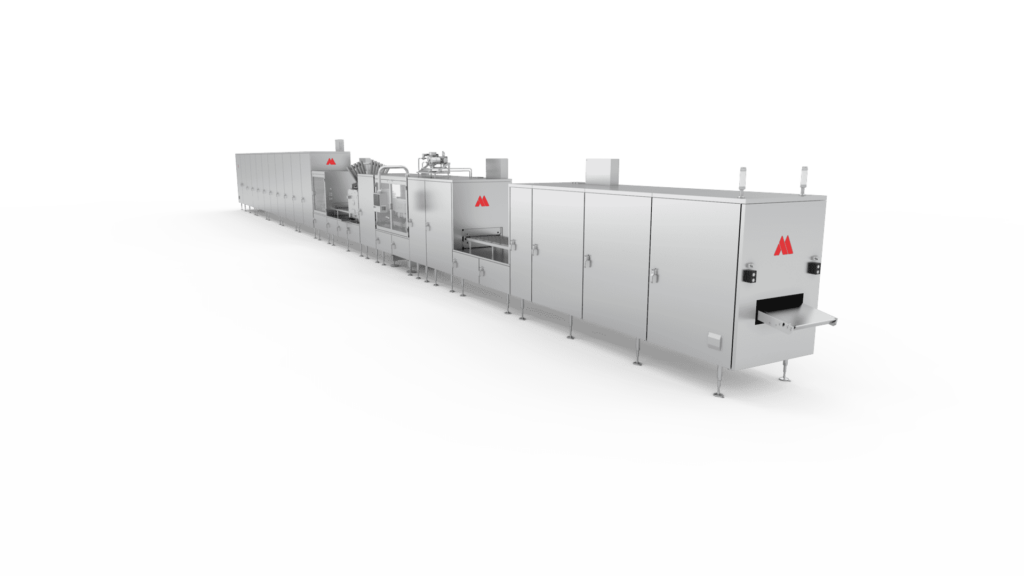

Steel Belt Line

- Handle production capacities from 250 to 6,600 kg/h.

- Ideal for producing chocolate chips, kisses, and shards.

- Achieve consistent product quality with advanced cooling and depositing systems.

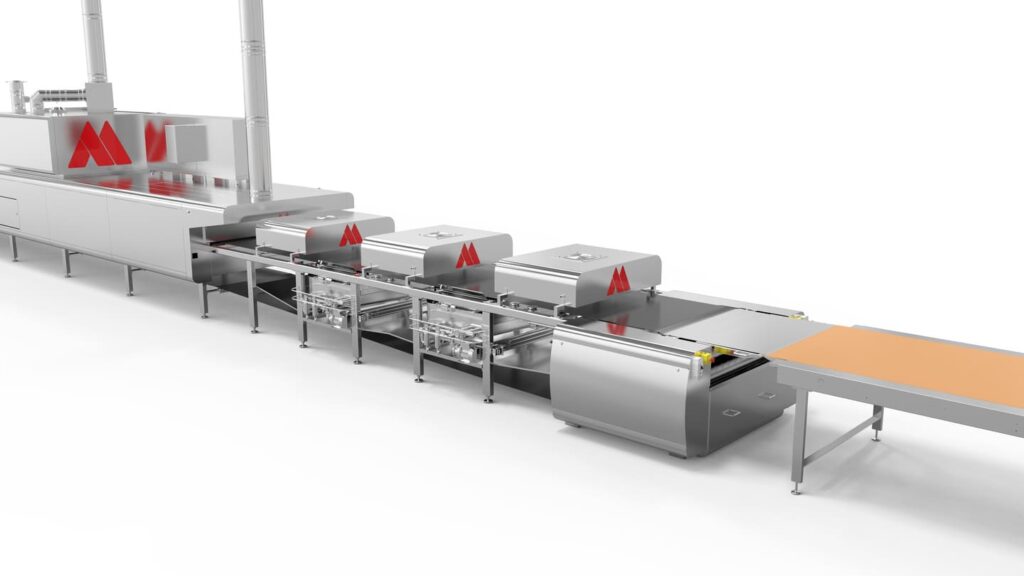

Eriksen Line

- Handle production capacities from 225 to 2,000 kg/h.

- Ideal for various products including small lentils, balls, eggs, toffee, and centers for polishing or sugar-dragée.

- Achieve exceptional product quality with cooled precision rollers and state-of-the-art technology.

Bakery Line

- Handle production of cookies with fruit, nuts, and chocolate pieces, as well as multi-layer or multi-mass cookies.

- Ideal for producing fully and partially enrobed cakes, and bottom-enrobed baked goods.

- Achieve consistent product quality with advanced depositing and enrobing systems.