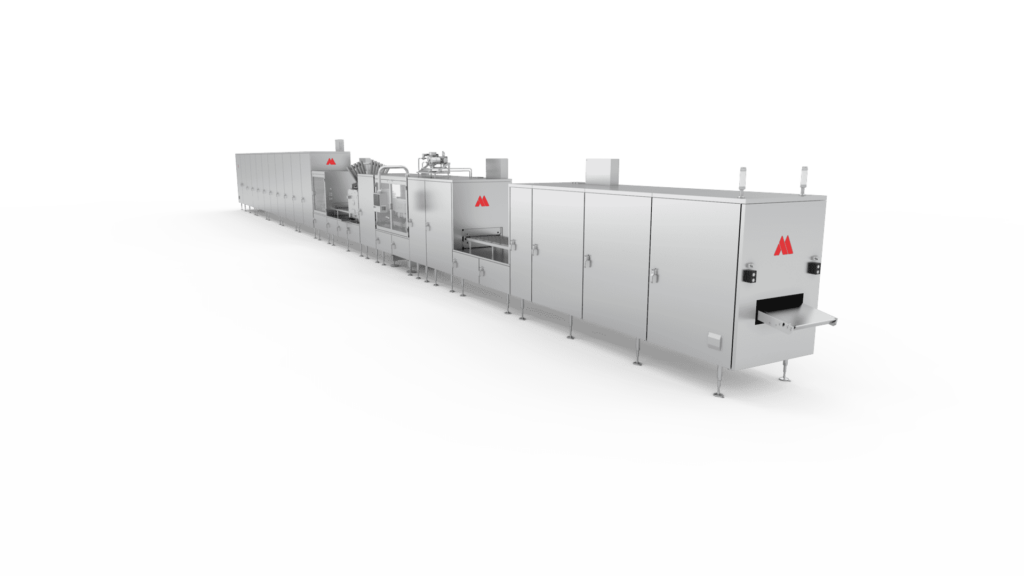

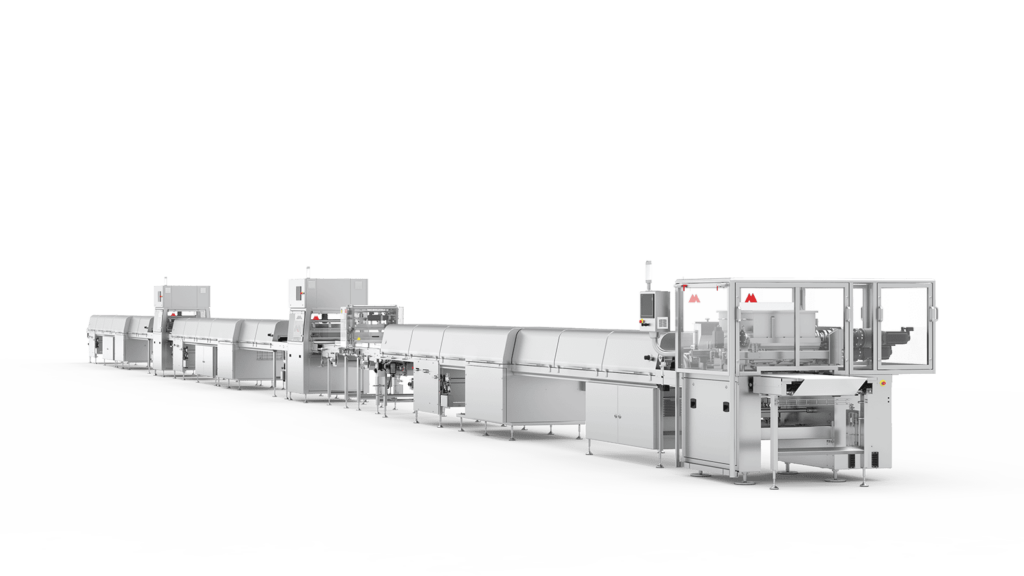

Universal Moulding Line

Experience the pinnacle of innovation and reliability with the Aasted Universal Moulding Line. Engineered for excellence, our line delivers unparalleled production capacity and precision, ensuring your confectionery creations reach new heights of quality and efficiency.

Explore the Universal Moulding Line

Solid moulding

Moulding of solid products with or without inclusions, with aeration, tablets, couvertures and combination of chocolate types. Moulding of products with solid centres such as wafers, biscuits centres, big inclusions and bars. Traditional inverting moulding of any shell, surprise and easter eggs.

One-shot moulding

One-shot moulding of center or solid filled chocolate articles with various ingredients e.g. nougat and caramel. Also possible in different chocolate types as well as different moulds for different shaped chocolate articles.

FrozenCone® with center

With a FrozenCone® module, the Universal line makes perfectly shaped cold-pressed shells for pralines, surprise eggs, tablets or any other “shell” product. With a ChocoAssort™ module, a robotic technique transfers the chocolate articles from moulds directly into boxes.

Aasted Smart Control™: Your Key to Seamless Operations

Our award-winning Aasted Smart Control™ is integrated into the Universal Moulding Line, offering an intuitive user interface designed for ease of use and efficiency. This advanced platform provides real-time insights and control over your entire production line, ensuring optimal performance and minimal downtime. With customizable settings and comprehensive monitoring capabilities, you can streamline operations and maintain consistent product quality effortlessly.

Specifications

| Type of production | Long and non-stop production; continuous mould movement Ideal for medium-high production capacity with low-mediun product complexity Custom designed to fit requirements and product complexity Easy maintenance |

| Final products | Filled chocolate tablets Bars Pralines Shells Solid articles Hollow articles |

| Moulding processes | Solid moulding Traditional shell moulding FrozenCone® shell moulding FrozenCone® assortment box One-shot & triple shot Centre fillings Mass with inclusions Aeration Caramel |

| Capacity | 1.000 – 10.000 kg/hour |

| Chain pitch | 8” – 16” |

| Depositing area | 170×370 – 370×1.070 |

| Sections | Mould changing, inspection, heating and cleaning Depositing and shaking Cold-pressing of chocolate shells (FrozenCone® technology) Suprise feeding Depositing of filling Center cooling Mould closing Cooling and conditioning Mould opening Demoulding |

| Compatible depositors | For the 700 mm lines Aasted offers EP2 depositor For the 1000 mm lines Aasted offers SE14 depositor Stainless steel and aluminum design |

| HMI | Interface for operating the line and the depositor |

Seamless installation and quick start with Aasted Universal Line

Installation overview

Our dedicated team ensures a smooth and efficient installation process. From initial setup to full operational status, we handle every detail to get your production line running seamlessly.

Training and support

We provide comprehensive training for your staff, ensuring they are well-versed in operating and maintaining the Universal Moulding Line. Our support doesn’t end after installation; we’re here to assist you whenever needed.

Maintenance and optimization

Regular maintenance and optimization services are available to keep your line running at peak performance. Our experts monitor your system and provide necessary adjustments to maintain efficiency and productivity.

Print materials & documents

Discover the Aasted Technology Center

Unlock new possibilities for your chocolate production by testing and refining your products at the Aasted Technology Center. Our state-of-the-art facility provides a unique opportunity to experiment with different formulations and processes, ensuring your products meet the highest standards of quality and innovation.

Learn more about the Universal Moulding Line

Our team is ready to provide you with detailed information and answer any questions you may have about the Universal Moulding Line. Discover how our innovative solutions can elevate your production capabilities and meet your specific needs. Don’t hesitate to reach out and explore the possibilities with Aasted.

Got questions about this product?

Fill out the short contact form, and we’ll get back to you with the information you need. Let’s find the right solution for your needs! Share your details, and we’ll connect you with the right expert to guide you every step of the way.

You can also click the button below and find the direct contact information for a specific Aasted employee.

Explore our wide product range

Jensen Line

- Capacity from 200 – 2,200 kg/hour.

- Suitable for the production of moulded articles with or without inclusions.

- Designed with low noise driving system with easy interactive HMI.

Confectionery Line

- Produce between 240 – 1,920 kg/h, perfect for scaling up your production.

- Achieve uniform size and shape with our advanced extrusion and cutting technology.

- Working widths ranging from 400 to 2x 800 mm and up to 2×16 rows across.

Steel Belt Line

- Handle production capacities from 250 to 6,600 kg/h.

- Ideal for producing chocolate chips, kisses, and shards.

- Achieve consistent product quality with advanced cooling and depositing systems.