SuperNova Energy Temper

The SuperNova Energy extends the chocolate’s time in the crystallization zone, utilizing unique scraper wings and precise temperature control. This design reduces energy consumption by up to 30% compared to traditional tempering machines.

Explore the SuperNova Energy Temper

Take the SuperNova Energy Temper for a 360° spin

Energy efficiency

The machine reduces energy consumption by up to 30% compared to traditional tempering machines, making it a cost-effective and environmentally friendly option.

Optimized tempering process

By keeping the chocolate at 1.5-2°C higher than traditional methods, the SuperNova Energy eliminates unwanted B3 and B4 crystals, ensuring only high-quality B5 crystals. This results in perfect chocolate coating and consistent liquidity, minimizing downtime and enabling efficient 24/7 production.

Enhanced chocolate quality

The SuperNova Energy maintains a constant tempering index, creating stable beta V crystals, which enhance the taste, texture, and consistency of the chocolate, resulting in a superior product.

Patented energy saving process

SuperNova Energy employs a patented energy-saving process that maintains chocolate at a slightly higher temperature than traditional methods. This eliminates lower-quality B3 and B4 crystals, ensuring only premium B5 crystals for perfect coating and enhanced product quality.

Cost efficiency and rapid ROI

Investing in SuperNova Energy typically yields a return within three years due to its energy efficiency, reduced downtime, and improved product quality. This makes it not only environmentally friendly but also financially advantageous for chocolate manufacturers.

User-friendly interface

The most simple and user-friendly interface ever made for a tempering machine.

While other tempering machines have complicated to use interface, our new patented software has a user-friendly and intuitive one. With the new software, it is effortless to adjust the exit temperature and the temper index separately. The user interface is developed for users by users and is specially produced by Aasted for the chocolate industry.

The types of SuperNova Energy

1. Energy Basic

Ideal for maintaining a continuous flow of perfectly tempered chocolate, ensuring only Beta V crystals. Energy technology enhances taste, texture, and break. Low maintenance, cost-effective solution. Capacity: 200kg/h to 12,000kg/h.

2. Energy PreTreat

Ensures stable chocolate temperature and minimizes fat-bloom. Ideal for stabilizing varying temperatures efficiently and safely. Capacity: 200kg/h to 8,000kg/h.

3. Energy CTS

Features a built-in tank and pump for easy mass feeding and quick production shifts. Energy technology enhances chocolate taste, break, and texture. Continuous Temperature System (CTS) allows inline production flexibility. Capacity: 200kg/h to 4,500kg/h.

Specifications

| Capacity | From 200kg/h to 12.000kg/h |

| Crystallization | Dense crystal structure with only Beta V crystals |

| Cooling time | Faster solidification for higher throughput |

| Fat migration | Slower fat migration |

| Viscosity | Lower viscosity for potential cocoa butter savings |

| Shelf-life | Longer shelf-life Better gloss Crispy break |

| Output temperature | Up to 2 degree higher output temperature |

| Energy consumption | The total energy consumption is up to 30% lower than a traditional tempering machine. |

| Versions | Energy Basic Energy PreTreat Energy CTS |

| Melting point | Higher melting point due to the 5-10 times longer high sheer crystal zones compared to normal industrial standard tempered machinery. |

| Power | 3 x 400 V, 50 Hz (CE) 3 x 460 V, 60 Hz (UL) (or according to agreement) |

| Electrical components | Allen Bradley or Siemens PLC and colour touch screen. Siemens PLC ET200SP, 12” HMI Type Siemens TP1200 Allen Bradley PLC L19ER, 12” HMI Type AB Type PanelView +7 |

Installation and getting started

Get started with minimal downtime

Get started with minimal downtime by choosing Aasted’s efficient solutions. Our advanced technology and expert support ensure your production runs smoothly from day one.

Ensuring quality with rigorous testing

We always test equipment before shipping to guarantee optimal performance and reliability for your production.

Seamless integration into your existing line

Our solutions are designed for easy integration, enhancing your current production setup without disruption.

Print materials & documents

Visit Aasted Technology Center

At Aasted Technology Center, you can explore and experiment with our wide range of machines for chocolate, bakery, and confectionery production. Our test center allows you to find the right solution for your needs, and see firsthand how Aasted Smart Control™ can reduce downtime, service, and maintenance costs. Fill in the form below or contact our sales manager to start exploring the possibilities with Aasted.

Reach out to hear more about the SuperNova Energy Temper

At Aasted, we prioritize your satisfaction with our dedicated customer service team. Whether you need technical support, product information, or assistance with an order, we are here to help you every step of the way.

Got questions about this product?

Fill out the short contact form, and we’ll get back to you with the information you need. Let’s find the right solution for your needs! Share your details, and we’ll connect you with the right expert to guide you every step of the way.

You can also click the button below and find the direct contact information for a specific Aasted employee.

Explore our wide product range

Jensen Line

- Capacity from 200 – 2,200 kg/hour.

- Suitable for the production of moulded articles with or without inclusions.

- Designed with low noise driving system with easy interactive HMI.

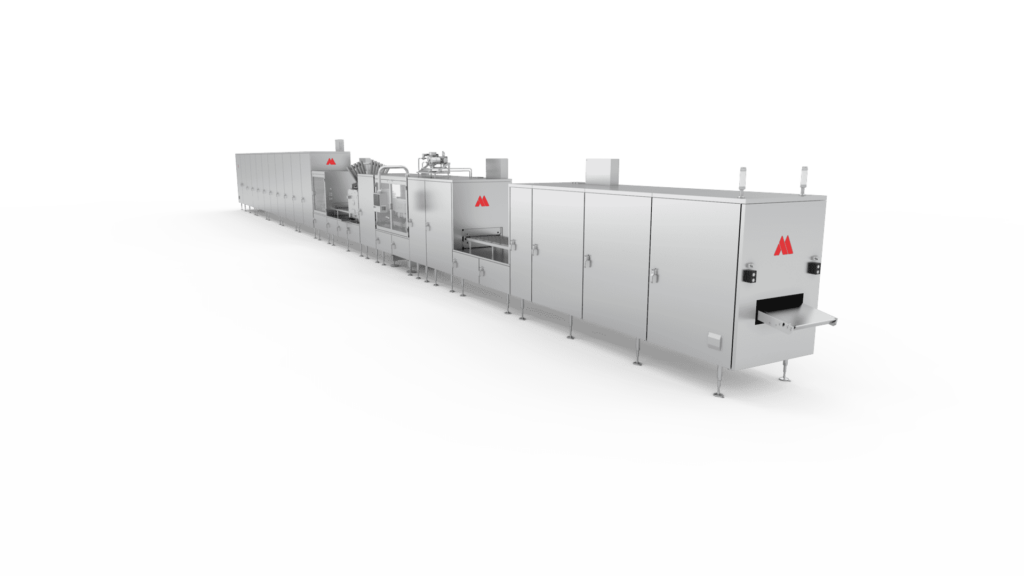

Universal Moulding Line

- Produce up to 10,000 kg/h – high-volume production with ease.

- Various chocolate moulding processes, including solid, shell, and FrozenCone®.

- Achieve consistent quality with our state-of-the-art depositing and cooling systems.

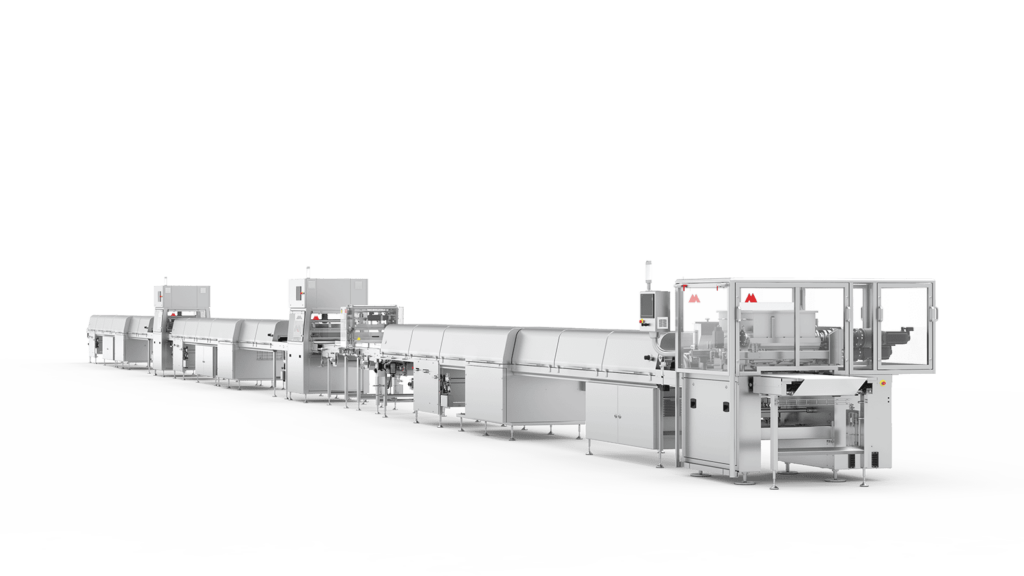

Confectionery Line

- Produce between 240 – 1,920 kg/h, perfect for scaling up your production.

- Achieve uniform size and shape with our advanced extrusion and cutting technology.

- Working widths ranging from 400 to 2x 800 mm and up to 2×16 rows across.