Master Enrober

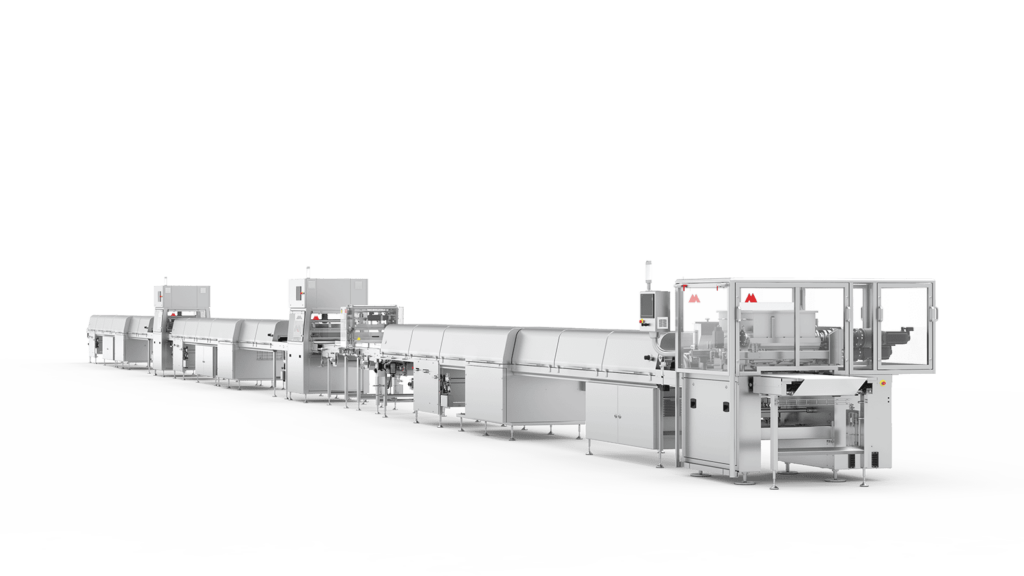

Experience unparalleled efficiency, reliability, and cost savings with the Nielsen Master Enrober, engineered with precision and innovation. Its unique detachable lower section enables swift and flexible changeovers between various enrobing materials, ensuring seamless operation for all your enrobing needs.

Explore the Aasted Nielsen Master Enrober

Take the Master Enrober for a 360° spin

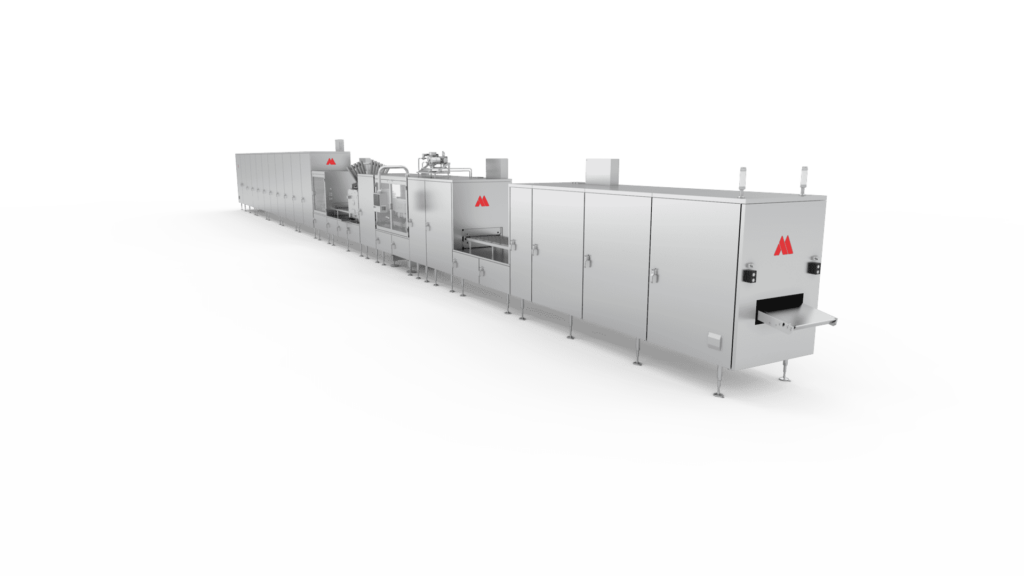

If you require large scale and fast production our Nielsen Master enrober comes in a XXL version for large scale enrobing. With two curtain boxes the XXL provides you flawless coating regardless of the speed and product.

Minimal water consumption with an advanced closed water system with built-in heat exchanger for precision temperature control.

Whether your product requires partial, bottom, side, or complete enrobing. The Master and Master XXL can be equipped with a range of auxiliary equipment to meet all your enrobing needs.

With our extensive experience and unparalleled expertise, we guarantee a perfect gloss, no matter which enrobing method you choose.

The Aasted Nielsen Master comes equipped with a user-friendly interface and advanced control systems.

Nielsen Master Enrober: Three versions for ultimate flexibility

Aasted’s Nielsen Master Enrober series offers three powerful versions, each designed to meet different production needs—from small-scale to large-scale manufacturing. Every version is built with the same focus on precision, energy efficiency, and reliable enrobing performance.

1. Standard version

The classic Nielsen Master Enrober is ideal for precise and consistent chocolate enrobing. Designed for small to large production lines, it delivers reliable and efficient performance. Whether you are enrobing cakes, bars, or other confectionery products, this enrober ensures perfect, uniform results every time.Features:

2. Energy version

The Nielsen Energy Enrober is optimized to reduce energy consumption without compromising quality. This version features an energy-efficient configuration that ensures low energy use while preventing blockages and maintaining a constant flow of tempered chocolate. It is the perfect choice for producers looking to reduce energy costs while maintaining consistent product quality.Features:

3. XXL version

For larger production lines, the Nielsen XXL Enrober is the ideal solution. With its expanded capacity, this version can handle large volumes, making it perfect for industrial-scale production. It ensures top-quality results, even with the most complex products, while handling higher production output.Features:

Save energy with the Master Energy

The Energy Enrobing Concept works by a direct injection of the tempered chocolate mass from the tempering machine to the consumption flow. In traditional enrobing machines though, you see mixing of the chocolate in the collecting tray. With the direct injection of finished tempered chocolate mass you are ensured a homogenous tempered mass. This result in a uniform tempering index in the enrober with constant temperature resulting in improved finished products.

Combining the Aasted Energy Enrobing Concept with an Aasted SuperNova Energy Tempering machine will enable energy savings compared to traditional tempering and enrobing methods. The combination will not only boost your energy savings but also enhance the quality of fat crystals and having a homogeneous tempered mass. Furthermore, a reduced cooling time need in the cooling tunnel.

Specifications

| Band speed | 2.18 – 12.63 m/min. |

| Band height | 1000 mm |

| Working direction | Left to right (LR) – or right to left (RL) |

| Power supply | 3 x 400 V, 50 Hz (CE) 3 x 460 V, 60 Hz (UL) |

| Electrical components | Allen Bradley or Siemens PLC with 12″ color touch screen |

| Infeed wire mesh table | 500 mm 1000 mm |

Installation and getting started

Get started with minimal downtime

Get started with minimal downtime by choosing Aasted’s efficient solutions. Our advanced technology and expert support ensure your production runs smoothly from day one.

Ensuring quality with rigorous testing

We always test equipment before shipping to guarantee optimal performance and reliability for your production.

Seamless integration into your existing line

Our solutions are designed for easy integration, enhancing your current production setup without disruption.

Print materials & documents

Visit Aasted Technology Center

At Aasted Technology Center, you can explore and experiment with our wide range of machines for chocolate, bakery, and confectionery production. Our test center allows you to find the right solution for your needs, and see firsthand how Aasted Smart Control™ can reduce downtime, service, and maintenance costs. Fill in the form below or contact our sales manager to start exploring the possibilities with Aasted.

Reach out to hear more about the Aasted Master Enrober

Our team is ready to provide you with detailed information and answer any questions about the Junior Enrober. Discover how our innovative solutions can enhance your production capabilities and meet your specific needs. Don’t hesitate to reach out and explore the possibilities with Aasted.

Got questions about this product?

Fill out the short contact form, and we’ll get back to you with the information you need. Let’s find the right solution for your needs! Share your details, and we’ll connect you with the right expert to guide you every step of the way.

You can also click the button below and find the direct contact information for a specific Aasted employee.

Explore our wide product range

Jensen Line

- Capacity from 200 – 2,200 kg/hour.

- Suitable for the production of moulded articles with or without inclusions.

- Designed with low noise driving system with easy interactive HMI.

Universal Moulding Line

- Produce up to 10,000 kg/h – high-volume production with ease.

- Various chocolate moulding processes, including solid, shell, and FrozenCone®.

- Achieve consistent quality with our state-of-the-art depositing and cooling systems.

Confectionery Line

- Produce between 240 – 1,920 kg/h, perfect for scaling up your production.

- Achieve uniform size and shape with our advanced extrusion and cutting technology.

- Working widths ranging from 400 to 2x 800 mm and up to 2×16 rows across.