Bottomer Enrober

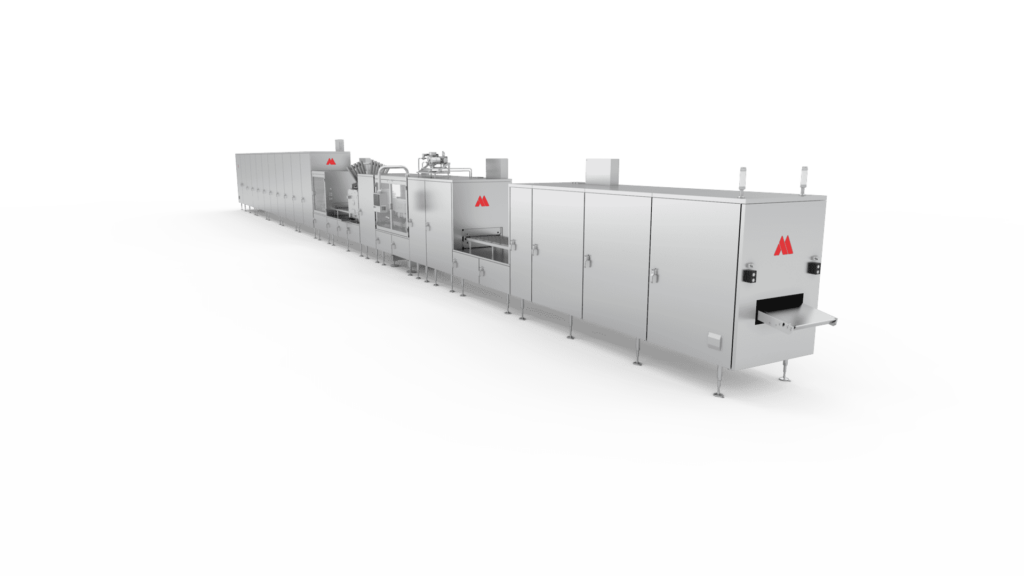

The Nielsen Bottomer is your advanced solution for bottom enrobing in the chocolate, bakery, and confectionery industries. Designed for precision and reliability, the Nielsen Bottomer ensures consistent high-quality coatings for a variety of products.

Explore the Junior Bottomer

Take the Bottomer for a 360° spin

Ideal for doughnuts, biscuits, and more, the Nielsen Bottomer offers precise bottom enrobing with chocolate and compound masses.

Built entirely in stainless steel, the bottomer guarantees durability, hygiene, and easy maintenance, essential for food production environments.

Featuring an advanced closed water system, the Nielsen Bottomer maintains precise temperature control, ensuring uniform coatings and operational efficiency.

Designed for continuous production, the bottomer supports three-shift operations, maximizing productivity and meeting high-demand scenarios.

With capabilities for left and right direction enrobing, the Nielsen Bottomer delivers uniform and precise coatings, enhancing product quality and consistency.

Specifications

| Band speed | 1.16 – 6.71 m/min |

| Band height | 1000 mm |

| Working direction | Left to right (LR) – or right to left (RL) |

| Power supply | 3 x 400 V, 50 Hz (CE)3 x 460 V, 60 Hz (UL) |

| Electrical components | Allen Bradley or Siemens PLC with 12″ color touch screen |

Installation & getting started

Get started with minimal downtime

Get started with minimal downtime by choosing Aasted’s efficient solutions. Our advanced technology and expert support ensure your production runs smoothly from day one.

Ensuring quality with rigorous testing

We always test equipment before shipping to guarantee optimal performance and reliability for your production.

Seamless integration into your existing line

Our solutions are designed for easy integration, enhancing your current production setup without disruption.

Print materials & documents

Visit Aasted Technology Center

At Aasted Technology Center, you can explore and experiment with our wide range of machines for chocolate, bakery, and confectionery production. Our test center allows you to find the right solution for your needs, and see firsthand how Aasted Smart Control™ can reduce downtime, service, and maintenance costs. Fill in the form below or contact our sales manager to start exploring the possibilities with Aasted.

Reach out to hear more about the Nielsen Bottomer

Our team is ready to provide you with detailed information and answer any questions about the Junior Bottomer. Discover how our innovative solutions can enhance your production capabilities and meet your specific needs. Don’t hesitate to reach out and explore the possibilities with Aasted.

Got questions about this product?

Fill out the short contact form, and we’ll get back to you with the information you need. Let’s find the right solution for your needs! Share your details, and we’ll connect you with the right expert to guide you every step of the way.

You can also click the button below and find the direct contact information for a specific Aasted employee.

Print materials & documents

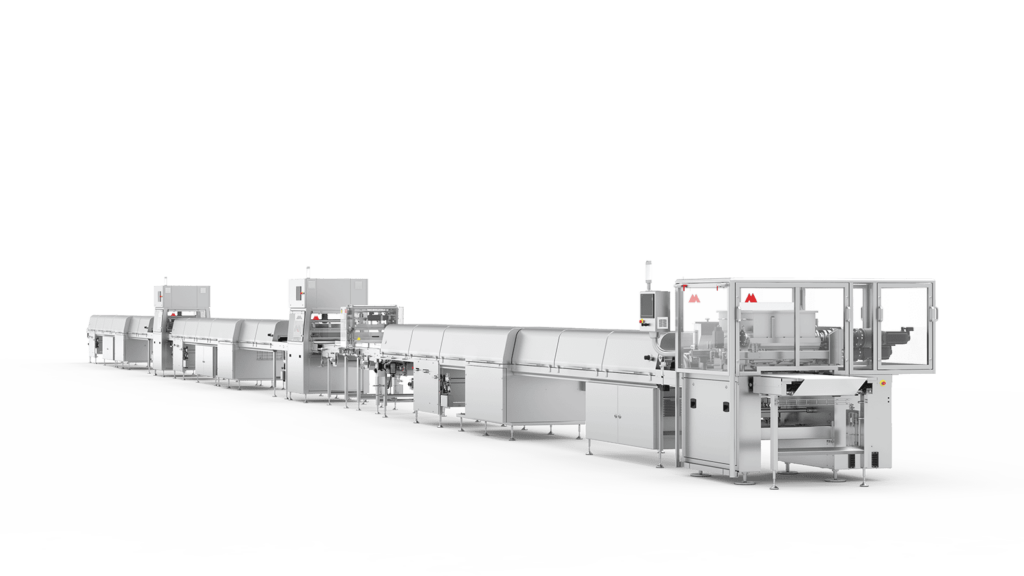

Jensen Line

- Capacity from 200 – 2,200 kg/hour.

- Suitable for the production of moulded articles with or without inclusions.

- Designed with low noise driving system with easy interactive HMI.

Universal Moulding Line

- Produce up to 10,000 kg/h – high-volume production with ease.

- Various chocolate moulding processes, including solid, shell, and FrozenCone®.

- Achieve consistent quality with our state-of-the-art depositing and cooling systems.

Confectionery Line

- Produce between 240 – 1,920 kg/h, perfect for scaling up your production.

- Achieve uniform size and shape with our advanced extrusion and cutting technology.

- Working widths ranging from 400 to 2x 800 mm and up to 2×16 rows across.