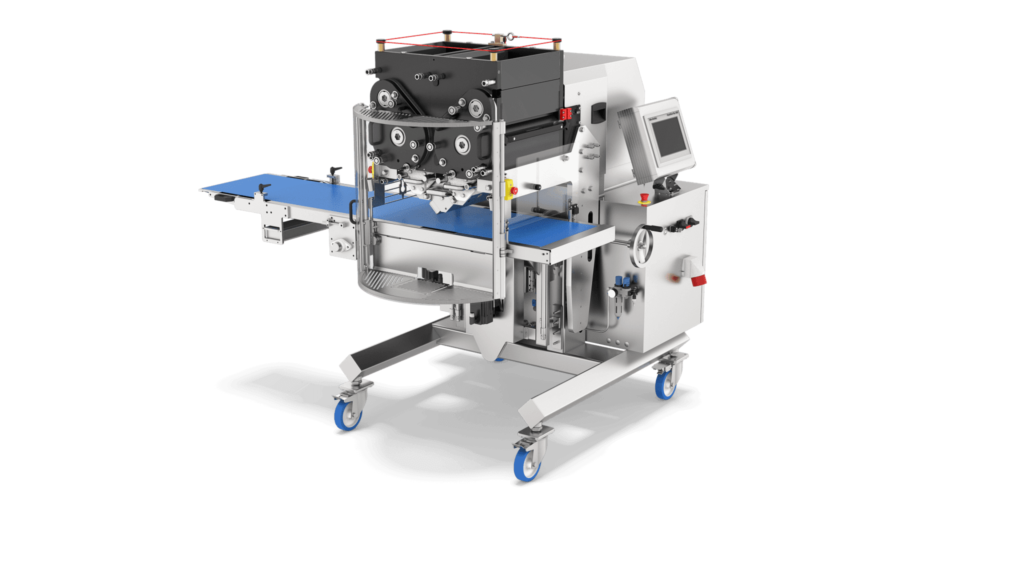

Alice™ C-Frame

The Alice™ C-Frame is a versatile depositor and extruder, perfect for small-scale production and laboratory environments. Designed to handle any type of mass, this machine allows you to work with up to three different masses simultaneously, giving you the freedom to be innovative and creative with your products.

Discover the Aasted Alice™ Compact

Take the Alice™ C-Frame for a 360° spin

FlexBooster™ & CamRotor™

The patented FlexBooster™ technology captures and handles masses in the hopper with reduced booster speed, acting as the main feed roller guiding mass to the CamRotor™.

The CamRotor™, a three-dimensional impeller, works with the FlexBooster™ to handle any mass with or without inclusion, creating a gentle suction lift and precise extrusion.

Together, FlexBooster™ and CamRotor™ enable creative freedom and flawless end results.

Cleaning and maintenance

The Alice™ is designed for you to have easy cleaning, quick changeover of production. All parts are light weight, easy to handle, and easily released and disassembled. As a unique feature the Alice™ allows complete hosing-down off-line.

The Alice™ allows unique removing of the chamber for complete hosedown making cleaning hassle free. In-line cleaning is also possible with dedicated tools assisting you in the cleaning process.

QuickShift™ Tools

Want to create a great variety of products? Quickshift tools allows you to be creative with the following options:

- One-shot

- Two-color mass extrusion and wire cutting or single-mass extrusion

- Wire cutting for large inclusions.

- Sequence depositing

- Single depositing and extrusion

- Depositing with pivoting motion

We also offer you customized tools made just for your requirements. This will enable you to create any shape and inclusion you want.

User-friendly interface

Unlike other machines with complicated interfaces, our new patented software boasts a user-friendly design. Developed by users for users, this interface is specifically tailored by Aasted to meet the needs of the bakery industry.

Specifications

| PLC | Siemens or Allen Bradley |

| HMI | 12” touch screen |

| Compressed air | Min. 6 bar (100 liter/hour) |

| Power supply | Single Head: Up to 10 kW Double Head: Up to 14 kW Triple Head: Up to 18 kW |

| Pre-feeding | 0.2 – 2.5 bar |

| Extruding | Max. 150 liter/hour per row |

| Z-motion | 70 mm |

| X-motion | 200 mm |

Installation and getting started

Get started with minimal downtime

Get started with minimal downtime by choosing Aasted’s efficient solutions. Our advanced technology and expert support ensure your production runs smoothly from day one.

Ensuring quality with rigorous testing

We always test equipment before shipping to guarantee optimal performance and reliability for your production.

Seamless integration into your existing line

Our solutions are designed for easy integration, enhancing your current production setup without disruption.

Print materials & documents

Visit Aasted Technology Center

At Aasted Technology Center, you can explore and experiment with our wide range of machines for chocolate, bakery, and confectionery production. Our test center allows you to find the right solution for your needs, and see firsthand how Aasted Smart Control™ can reduce downtime, service, and maintenance costs. Fill in the form below or contact our sales manager to start exploring the possibilities with Aasted.

Reach out to hear more about the Alice™ C-Frame

At Aasted, we prioritize your satisfaction with our dedicated customer service team. Whether you need technical support, product information, or assistance with an order, we are here to help you every step of the way.

Got questions about this product?

Fill out the short contact form, and we’ll get back to you with the information you need. Let’s find the right solution for your needs! Share your details, and we’ll connect you with the right expert to guide you every step of the way.

You can also click the button below and find the direct contact information for a specific Aasted employee.

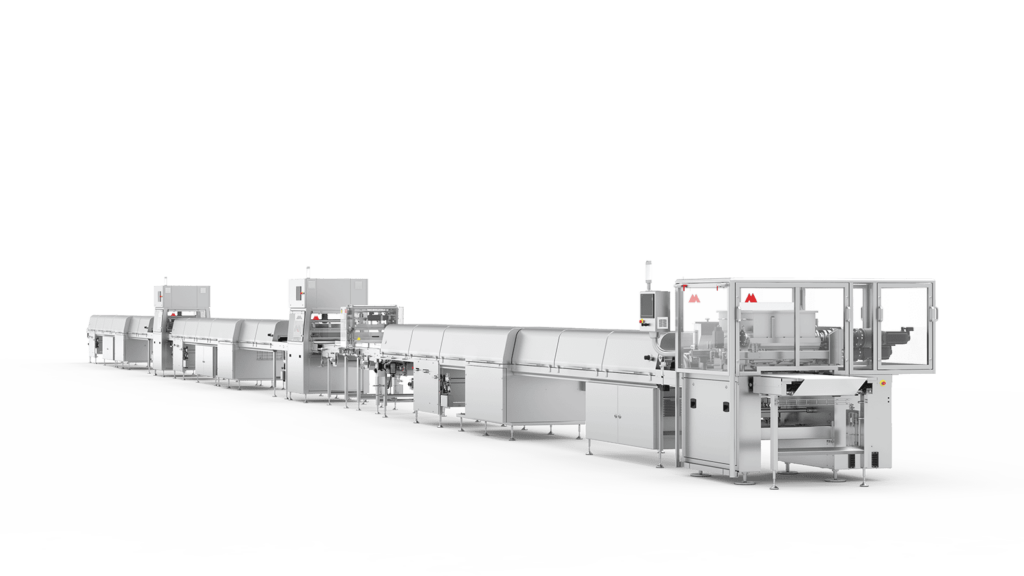

Explore our wide product range

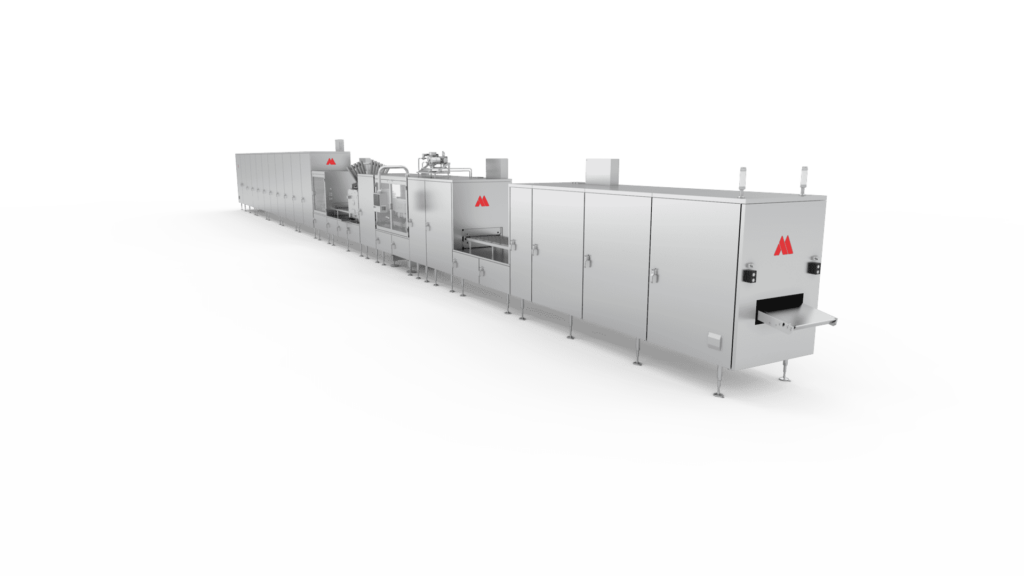

Jensen Line

- Capacity from 200 – 2,200 kg/hour.

- Suitable for the production of moulded articles with or without inclusions.

- Designed with low noise driving system with easy interactive HMI.

Universal Moulding Line

- Produce up to 10,000 kg/h – high-volume production with ease.

- Various chocolate moulding processes, including solid, shell, and FrozenCone®.

- Achieve consistent quality with our state-of-the-art depositing and cooling systems.

Confectionery Line

- Produce between 240 – 1,920 kg/h, perfect for scaling up your production.

- Achieve uniform size and shape with our advanced extrusion and cutting technology.

- Working widths ranging from 400 to 2x 800 mm and up to 2×16 rows across.